Эффективность производства, аналитика АСУ ТП

-

AllCtrl.SCADA на 1С

- Удобство Мнемосхемы на 1С

- Пульт диспетчера АСУ ТП: скорость, снижение затрат

- Разнообразие устройств OPC-клиент на базе 1С

- Управление простоями оборудования (ТОиР)

- Автоматизация — правила принятия решений в АСУ ТП

- Web, Intranet, Internet, интеграция АСУ ТП с ERP/1C

- Эффективность производства, аналитика

- Плановое обслуживание. Ремонты и запчасти (ТОиР)

-

Производство

- Удобство Мнемосхемы на 1С

- Пульт диспетчера АСУ ТП: скорость, снижение затрат

- Управление простоями оборудования (ТОиР)

- Управление инженерыми системами

- Автоматизация — правила принятия решений в АСУ ТП

- Web, Intranet, Internet, интеграция с ERP/1C

- Эффективность производства, аналитика

- Легкость в работе, простота в адаптации — 1С 8.3

Стоимость SCADA, 1C АСУ ТП, ТОиР, MES

Production efficiency, analytics in 1C ACS AllCtrl.SCADA

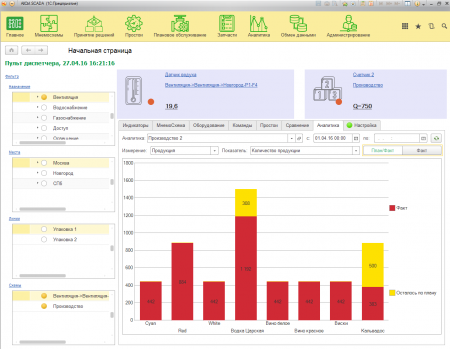

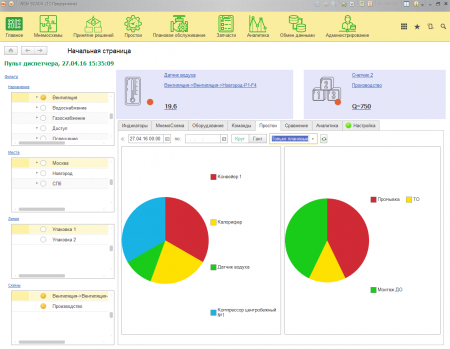

The integrated data analysis system allows receiving real-time information about the performance of both the enterprise or its unit and the specific equipment. Both plan-actual and plan-factor types of analysis are available to the user.

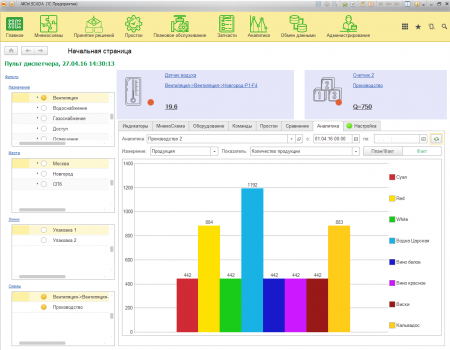

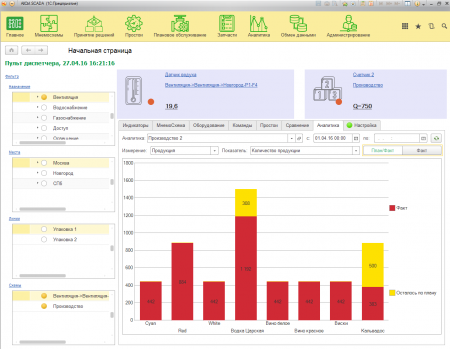

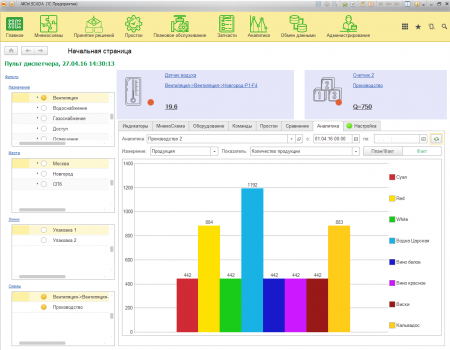

The histograms can be used to see how much specific products are produced. Analytical indicators can be used to determine how much of the product has been produced and how much is left up to the implementation of the plan.

It is easy to collect data from various types of production facilities. Information from a variety of data sources (programmable logical controller, I/O modules, network equipment, and HMI (Human-machine Interface) applications) is stored to generate real-time reporting and analysis.

Up to 80% of the production budget is usually spent on building and further support of data storage systems in working condition. Sharing of archival data is an integral part of the work in the developed automated control systems. Therefore, the need to create "cloud" resources for computing, data transfer and storage is becoming apparent. Data analysis systems allow you to rent infrastructure and its components, paying for only those resources that are actually used in production.

The histograms can be used to see how much specific products are produced. Analytical indicators can be used to determine how much of the product has been produced and how much is left up to the implementation of the plan.

It is easy to collect data from various types of production facilities. Information from a variety of data sources (programmable logical controller, I/O modules, network equipment, and HMI (Human-machine Interface) applications) is stored to generate real-time reporting and analysis.

Up to 80% of the production budget is usually spent on building and further support of data storage systems in working condition. Sharing of archival data is an integral part of the work in the developed automated control systems. Therefore, the need to create "cloud" resources for computing, data transfer and storage is becoming apparent. Data analysis systems allow you to rent infrastructure and its components, paying for only those resources that are actually used in production.

Total production histogram

Histogram of plan-actual analysis of production

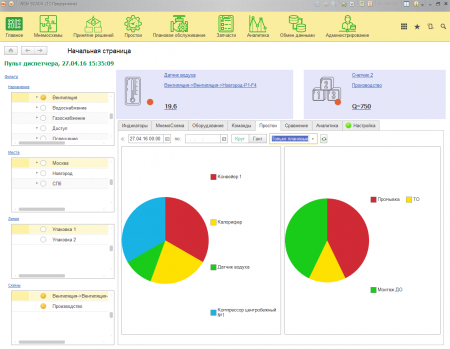

Histogram of downtime by hardware or by the reasons for downtime

- AllCtrl.SCADA на 1С

- Удобство Мнемосхемы на 1С

- Пульт диспетчера АСУ ТП: скорость, снижение затрат

- Разнообразие устройств OPC-клиент на базе 1С

- Управление простоями оборудования (ТОиР)

- Автоматизация — правила принятия решений в АСУ ТП

- Web, Intranet, Internet, интеграция АСУ ТП с ERP/1C

- Эффективность производства, аналитика

- Плановое обслуживание. Ремонты и запчасти (ТОиР)

- теплицы

- Удобство Мнемосхемы на 1С

- Пульт диспетчера АСУ ТП: скорость, снижение затрат

- Управление освещенностью

- Управление влажностью

- Управление поливом и подкормкой

- Системный подход к управлению микроклиматом

- Управление фрамугами

- Управление подачей СО2

- ЖИвотноводство

- Управление отоплением

- Пульт диспетчера АСУ ТП: скорость, снижение затрат

- Управление освещенностью

- Управление влажностью

- Управление кормлением

- Web, Intranet, Internet, интеграция с ERP/1C

- Эффективность производства, аналитика

- Легкость в работе, простота в адаптации — 1С 8.3

- Здания и жкх

- Управление вентиляцией

- Пульт диспетчера АСУ ТП: скорость, снижение затрат

- Управление освещенностью

- Управление электроснабжением

- Управление теплоснабжением

- Web, Intranet, Internet, интеграция с ERP/1C

- Эффективность управления, аналитика

- Управление доступом

- ПРоизводство

- Удобство Мнемосхемы на 1С

- Пульт диспетчера АСУ ТП: скорость, снижение затрат

- Управление простоями оборудования (ТОиР)

- Управление инженерыми системами

- Автоматизация — правила принятия решений в АСУ ТП

- Web, Intranet, Internet, интеграция с ERP/1C

- Эффективность производства, аналитика

- Легкость в работе, простота в адаптации — 1С 8.3

- © AllCtrl — Автоматизация управления оборудованием, 2016

Eng

Eng De

De Ru

Ru